Home > News > Industry news Industry news

Starting from scratch on papermaking (12): After much anticipation, the paper machine part has arrived

Release time:2024-07-01 08:57:00

Author: Dr. Fernando Mora;

contact information: fmvconsulting.fr@gmail.com

Editor and Proofreader: Dr. Zeng Xiling

Author Introduction

Dr. Fernando Mora is from France and has over 40 years of experience in the paper industry. He has worked in product development for leading companies in the paper industry, such as International Paper, Aussadat Rey, Ahlstrom, and has also worked in Europe, the United States, and China. He was a member of the board of directors of the French Centre for Paper Technology (CTP). Dr. Fernando Mora is one of the pioneers in researching biotechnology and microfiber papermaking. He has obtained multiple patents on paper products and specialty paper production, one of which is a highly innovative patent on the production of composite materials using pure mineral fibers. He has also collaborated with the French National Centre for Scientific Research (CNRS) to carry out prospective work on supramolecular characterization of fiber cell wall components using glucosidase.

01 Introduction

Starting from scratch on papermaking "has been published for 11 issues. This series of articles is actually composed of two intertwined parts, one is the main thread of pulp and papermaking, and the other is an important interpretation of paper properties. The two authors are Dr. Elias Retinanen and Dr. Fernando Mora, whom I highly respect. Readers interested in this series of articles can review the articles previously published by Paper Research Institute.

Regarding the main thread of pulp and paper making, in previous articles, we have introduced what happens to fibers before they arrive at the paper machine (i.e. pulping and grinding). Welcome back to the following articles.

Starting from scratch on papermaking (10):; Grinding” It is indeed complex, but it is worth every papermaker to understand!

Starting from scratch on papermaking (9): The core knowledge points of pulp bleaching are all here!

Starting from scratch on papermaking: exploring the process of wood turning into pulp (Part 2)

Starting from scratch on papermaking: exploring the process of wood turning into pulp (Part 1)

Starting from scratch on papermaking (II): Plant fibers for papermaking

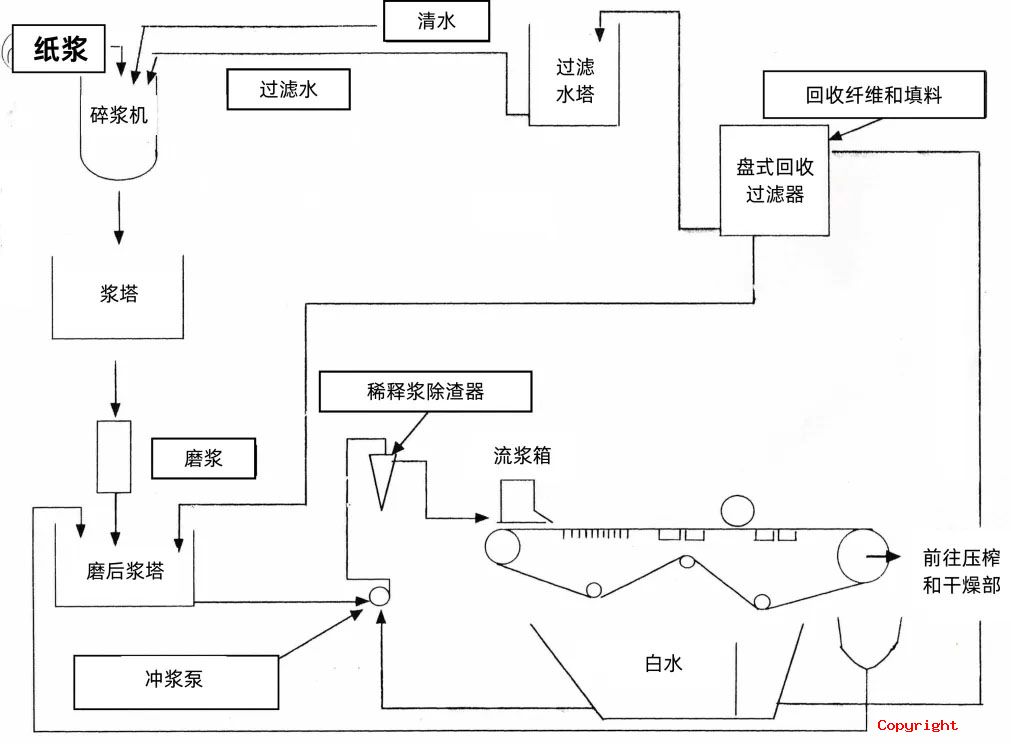

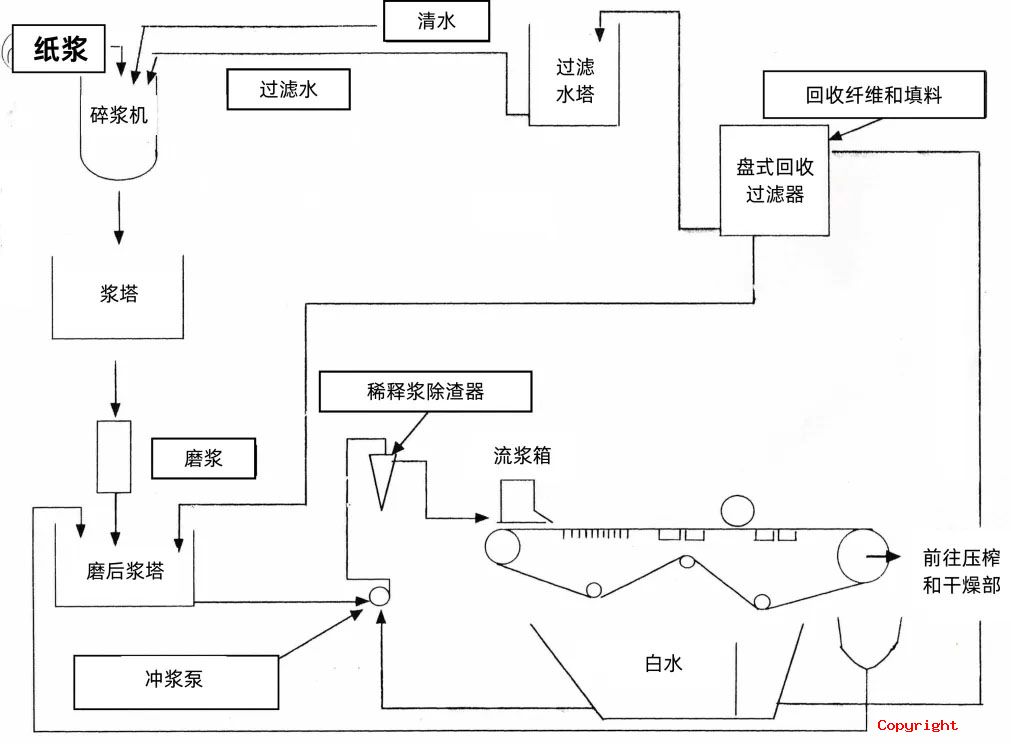

Now, let's take a look at what will happen next. After grinding, the fibers enter what is called“ Wet end; The place where the fibers are diluted, chemically treated, and purified before reaching the headstock of the paper machine, which is the first part of the paper machine. The following is a schematic description of the wet end of a paper machine:

02 wet-end chemistry

In the wet end of a paper machine (wet end chemical treatment), the following chemical products are usually added to the fibers:

Mineral fillers: clay, talc powder, GCC (ground calcium carbonate), PCC (precipitated calcium carbonate), etc. These are the most commonly used minerals, as well as titanium dioxide or synthetic particles (when high opacity is required for paper);

Resin for sizing: ASA (vinyl succinic anhydride), AKD (alkyl ketone dimer for neutral sizing), rosin is used for sizing under acidic conditions to make the paper hydrophobic;

Cationic starch: improves the strength of paper; (Finally got a chance to systematically understand it! Starch and Paper Application: Have you used starch well?)

Wet strength resin: improves the strength of paper in a wet state;

Optical whitening agent: improves the brightness of paper;

Process additives: improve the performance of paper machines (retain additives, defoamers);

Different additives (oil resistant agents, anti-counterfeiting and tamper proof products, dyes, etc.);

Of course, there is also water.

The following are typical locations for adding these chemicals:

03 paper machine

The paper machine is like a cathedral that integrates numerous technologies, with a cost that can reach billions of yuan. Therefore, it is very important to make the appropriate and correct choice based on the type of paper you want to produce.

In fact, a paper machine is a dewatering machine. Let's take the production of 80 grams per square meter of photocopy paper as an example, with a final moisture content of 4.5%. For producing 100 kilograms of paper, assuming a fiber retention rate of 100%, you will receive the following data:

In front of the net box (concentration=0.8%)

Fiber: 95.5 kilograms

Water: 11842 kilograms

Net end (dryness=20%)

Fiber: 95.5 kilograms

Remaining water: 382 kilograms

Remove water: 11460 kilograms

Extraction area outlet (dryness=48%)

Fiber: 95.5 kilograms

Remaining water: 104 kilograms

Remove water: 278 kilograms

End of dryer (dryness=95.5%)

Fiber: 95.5 kilograms

Remaining water: 4.5 kilograms/div>

This configuration allows the paper to receive good support and dehydration in both directions, thereby improving production efficiency and paper quality.

Remove water: 99.5 kilograms

So far, water has mainly been removed in the mesh section, and the remaining water after filtration in the mesh section is more difficult to remove, requiring the installation of expensive equipment (pressing section, drying section), which are also high energy consuming users (especially the drying section).

04 Long net paper machine

There are different systems that remove moisture through filtration after the net box. The most common is the Fourdrinier paper machine

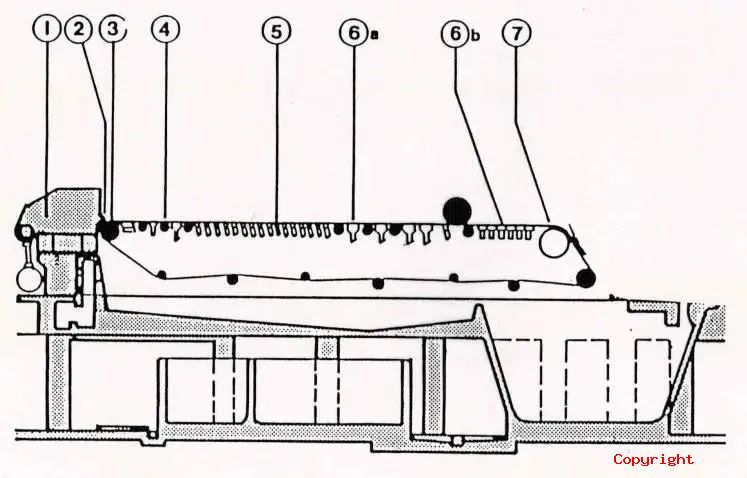

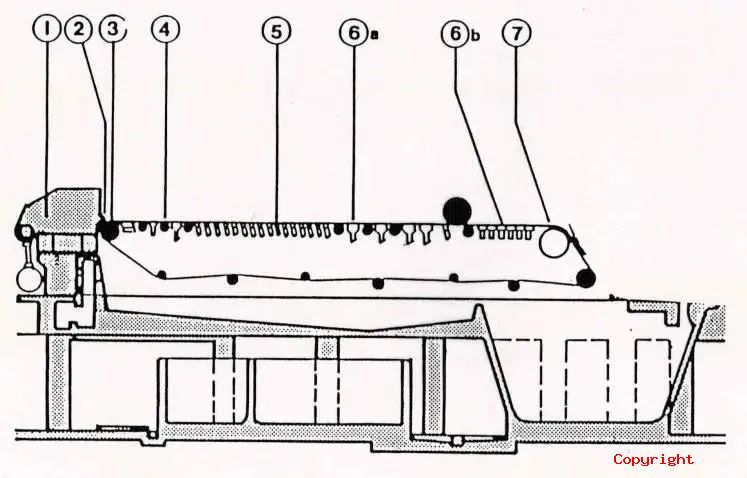

1. Slurry box; 2. Lips and mouth; 3. Front box roller; 4. Dehydration roller; 5. Wiper board; 6. Vacuum box; 7. Vacuum roller (driving roller)

1. Slurry box; 2. Lips and mouth; 3. Front box roller; 4. Dehydration roller; 5. Wiper board; 6. Vacuum box; 7. Vacuum roller (driving roller)

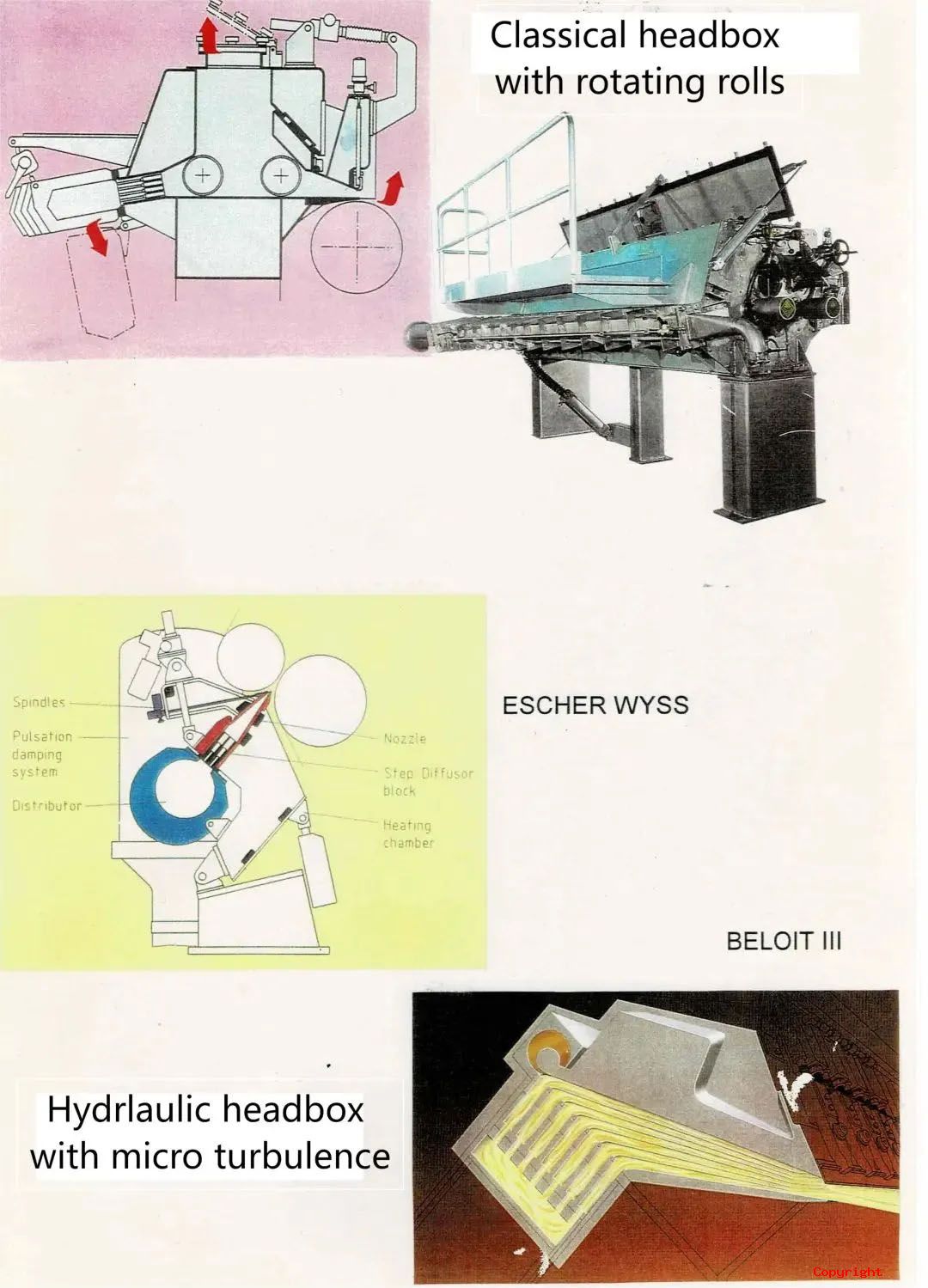

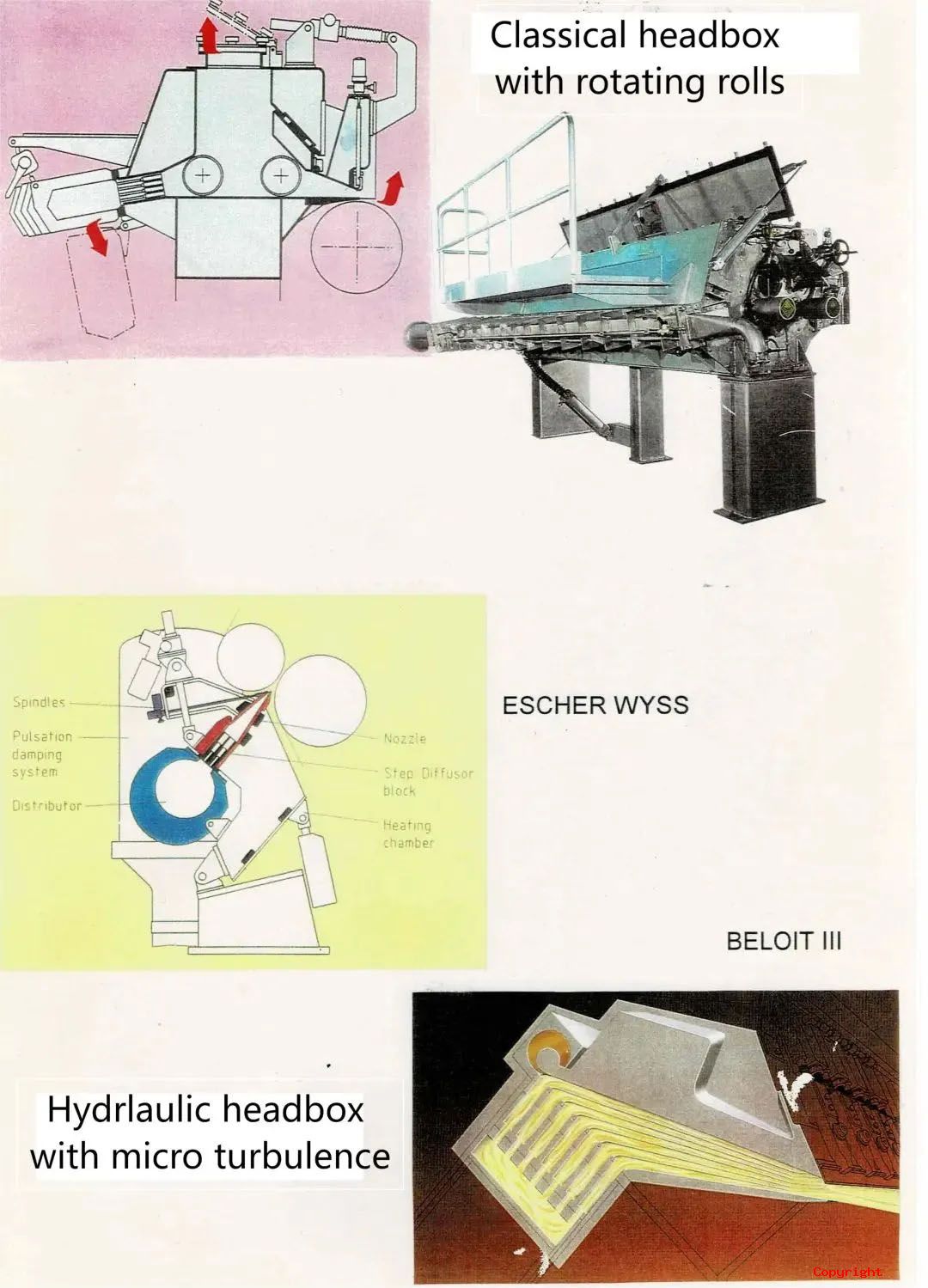

Different headboxes can be installed on the long web paper machine, such as a typical headbox with two homogenizing rollers or a hydraulic headbox (as shown in the figure below).

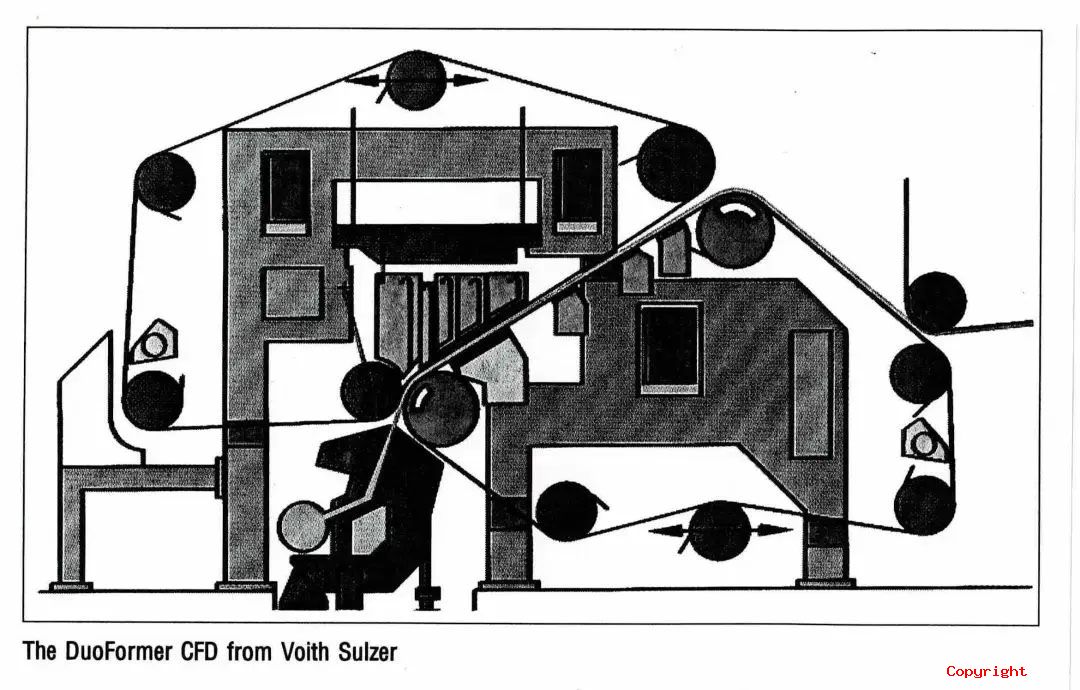

05 夹网造纸机

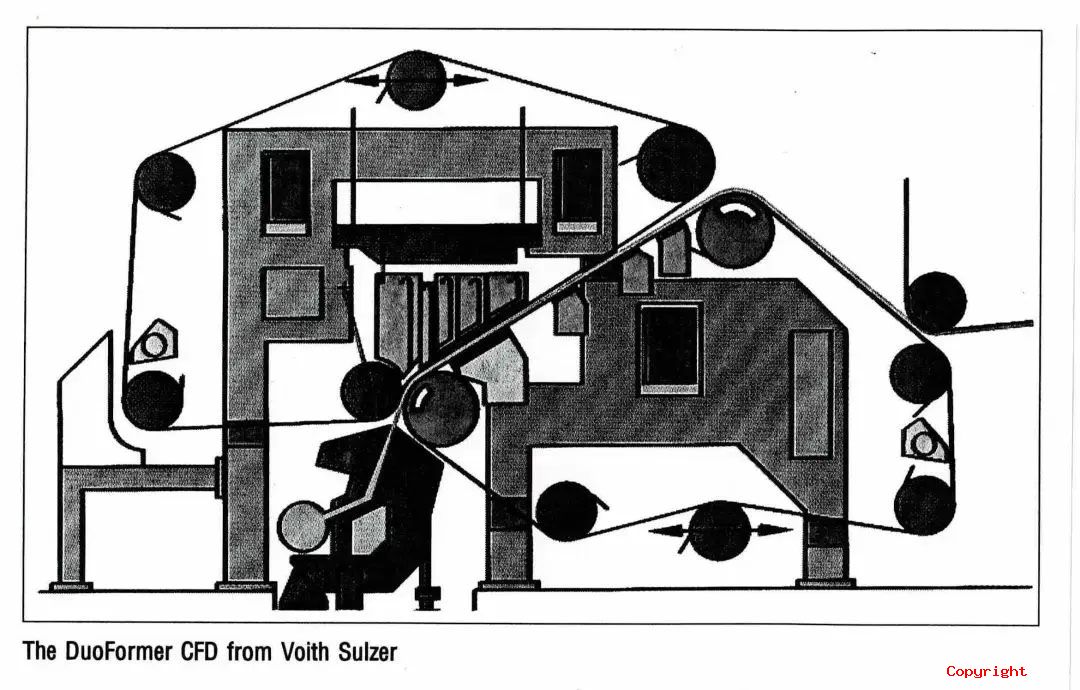

Twin wires paper machinesIt is a machine that uses two mesh parts in the papermaking process to improve water filtration efficiency. In order to enhance the water filtration effect, the high-speed paper machine is equipped with two mesh parts (one on one side of the fiber mesh and the other on the other side), which can make the paper more evenly dehydrated during the formation process.

This configuration allows the paper to receive good support and dehydration in both directions, thereby improving production efficiency and paper quality.

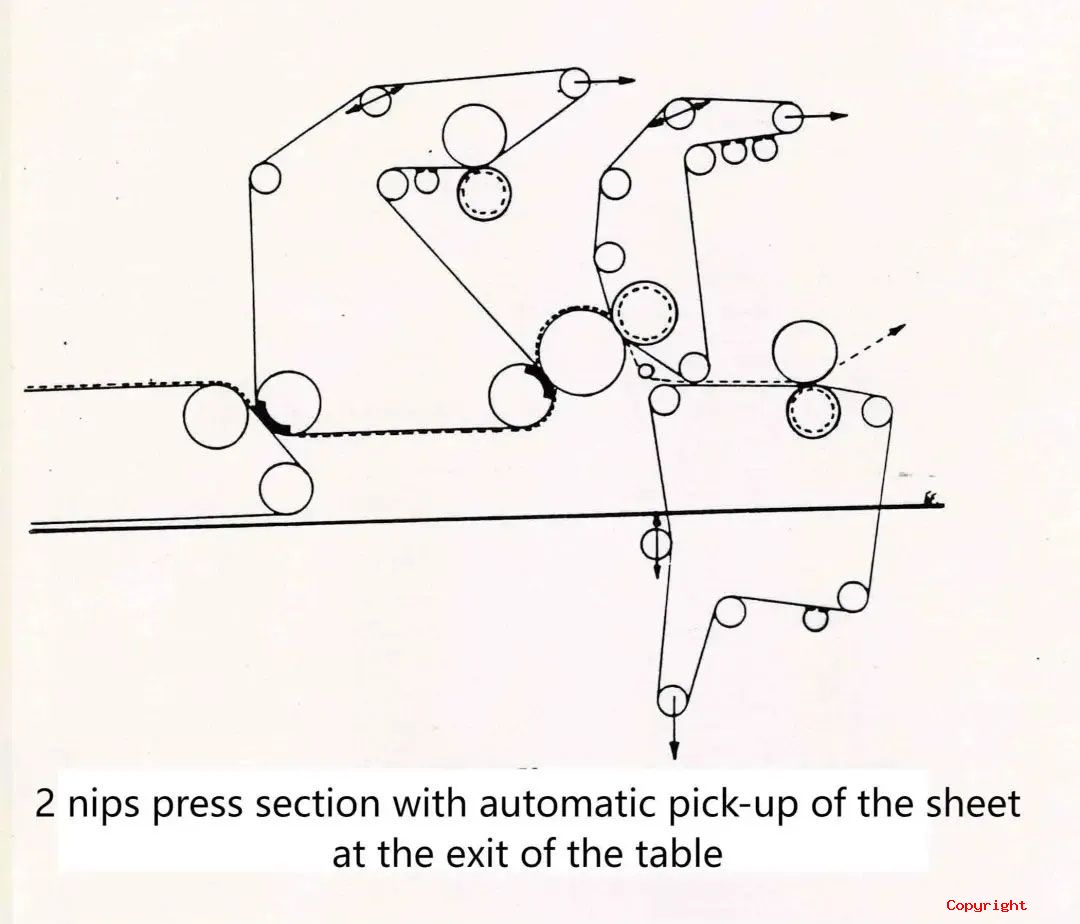

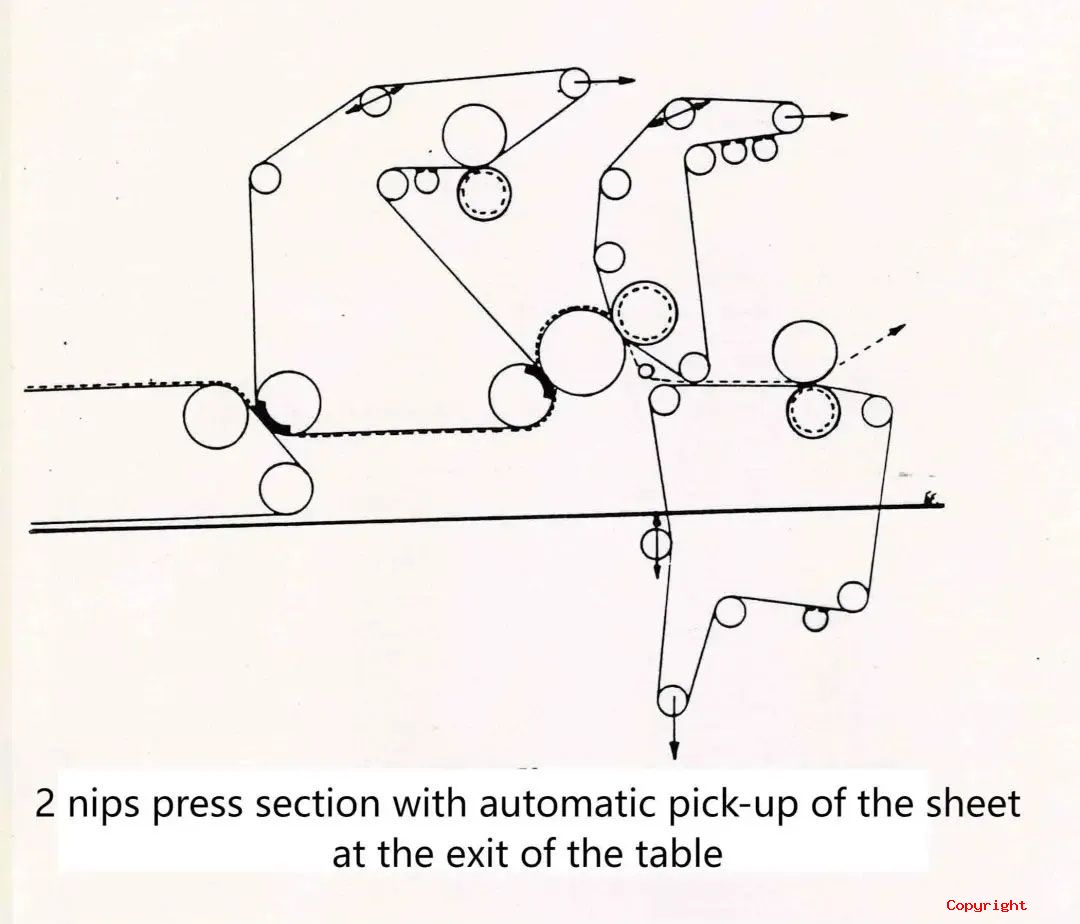

Squeezing section: The wet paper web is subjected to mechanical squeezing between the pressure rollers in the squeezing section to remove moisture.

Drying section: The drying section uses a steam heated dryer to achieve the desired dryness of the paper.

Drying section: The drying section uses a steam heated dryer to achieve the desired dryness of the paper.

06 Exam 1: How much do you know about papermaking?

The previous topic was: Which of the following is unrelated to Schopper data?

Answer revealed: The answer is the third one. Schopper is not a motorcycle brand, but Chopper is a motorcycle brand, as shown in the following picture:

What is Paper Research Garden?

Zhiyanyuan is a platform that shares the entire pulp and paper industry chain; Things” A platform for sharing stories with people.

“ Things” It refers to the knowledge, technology, experience, popular science, scientific research achievements, and information related to the entire upstream and downstream of the pulp and paper industry chain;

The stories of people include the life stories of employees in the pulp and paper industry, as well as the self media entrepreneurship story of Paper Research Garden, to witness each other's growth and inspire thinking.